India turns to hydroponic technology to meet fodder need

Hydroponic fodder production involves growing grains of cereal or legume without soil.

Hydroponic fodder unit at Khapuria, Cuttack

Indian states have turned to hydroponic technology (raising of plants without soil) to feed their livestock as there is a scarcity of cattle feed and the cost of the available packaged feed is spiraling.

This move is likely to revitalise the dairy sector of the country. With 146.31 million tonne production in 2015-16 India now stands as world’s top producer of milk.

Hydroponic fodder unit at Khapuria, Cuttack

The top milk producing states are Uttar Pradesh, Rajasthan, Andhra Pradesh, Gujarat, Punjab, Madhya Pradesh, Maharashtra, Haryana, Tamil Nadu and Bihar.

Many of these states have already established hydroponic fodder units to help the dairy farmers. However, milk productivity per animal in the country is still considered far less than the average in developed dairy nations.

India needs to focus on implementing technologies to enhance the output per animal, Union agriculture minister Radha Mohan Singh said recently.

Hydroponic fodder unit at Khapuria, Cuttack

Hydroponic fodder will help dairy farmers facing scarcity for quality cattle feed, especially those in urban areas who do not have enough land to cultivate the required quantity of green fodder.

Under Rashtriya Krishi Vikas Yojna the federal government has been encouraging the states to set up such units.

While Kerala Dairy Development Department (KDDD) has distributed 24 hydroponic fodder units to select dairy farmers, one hydroponics green fodder production unit has been established recently by Goa Dairy at Indian Council of Agricultural Research ( ICAR) complex in Goa.

The Punjab Agricultural University (PAU) has developed a low-cost indigenous greenhouse hydroponic technology that will help provide farmers higher vegetable yields with the use of less water and nutrient consumption.

Hydroponic fodder unit at Khapuria, Cuttack

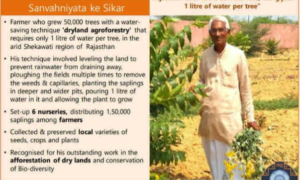

A state like Odisha often faces severe drought and fodder shortage, too has established its first automatic hydroponic fodder unit at Khapuria in the district of Cuttack. It was made operational this week to ensure a continuous supply of green fodder for the bulls maintained in the farm.

“This technology is first of its kind to be introduced in our state for fodder production. Fodder production is a crucial activity to make dairy as an economically viable enterprise,” secretary of Odisha’s fisheries and animal resources department Bishnupada Sethi said.

Feeding green fodder is essential for the economic production of milch animals as well as for maintaining good health of livestock. Hydroponic fodder is considered as one of the feasible solutions and most advanced technology available to solve the shortage of concentrates and fodder, he told Big Wire.

Production of hydroponic fodder is the most advanced technology in fodder production in the world, he pointed out.

Hydroponic fodder production involves growing grains of cereal or legume without soil. Usually, maize, oats and barley seeds are used for growing inside hydroponic machines. Seeds are allowed to grow under controlled environments such as humidity and temperature.

Optimum water and nutrient rich solutions are provided for growing of the seed. The grain responds to the supply of moisture and nutrients by sprouting and then producing a long vegetative green shoot with interwoven roots over a period of five to eight days.

A layer of succulent and fresh green forage is obtained, free of harmful organisms, sweet and tasty with a high nutritional value, and ready to be used as animal feed.

The nutritive value of hydroponic fodder is excellent and the most suitable option for the replacement of concentrates. Sprouted seedlings are more palatable, and sprouting enables all the nutrients in easily absorbable form.

Three hydroponic mats (10 kg each mat) per day is sufficient to meet the nutritional requirement of a cow yielding 15 litres a day. Only 10 kgs of green fodders and three kgs of dry fodders are required as supplementary feed.

Due to the high nutrient content of this fodder, maximum milk production potentiality of the milch animals can be ensured (up to 20 percent more). Optimum use of natural resources like water is made since one kg of hydroponic fodder production requires only two litres of water.

There is no need of inputs like manure, fertilizer, and pesticides, which reduce the cost of fodder production.The temperature and humidity are controlled automatically and kept within a range. The seeds are grown in trays and the water is provided according to the requirement.

No fertilizer or other inputs are provided for the sprout and it is allowed to grow aseptically. The entire unit is controlled electronically and the parameters are monitored through displays.

“The Odisha unit will be used for the demonstration purpose to encourage other prospective entrepreneurs to set up such units in future”, Sethi said.

Big Wire